Cranes are primarily used to transport and hoist heavy materials from one location to another.

Types of cranes at construction site

There are various types of cranes used at construction sites, each with its unique features and capabilities. Here are some of the most common types of cranes used in construction:

- Tower cranes: These are tall, stationary cranes that are typically used in the construction of high-rise buildings. They have a long horizontal arm (jib) that can be raised and lowered, and a counterweight to provide stability.

- Mobile cranes: These cranes are mounted on wheeled vehicles or tracks and can be easily moved around the construction site. They are typically used for heavy lifting tasks and have a telescopic boom that can extend to great heights.

- Rough terrain cranes: As the name suggests, these cranes are designed for use on rough and uneven terrain. They have large, wide wheels and are often used in off-road construction sites.

- Crawler cranes: These cranes have tracks instead of wheels and can be used on soft ground or in areas where a wheeled vehicle might get stuck. They are typically used for heavy lifting tasks and have a wide range of motion.

- Overhead cranes: These cranes are mounted on rails or beams and are used to move heavy loads horizontally along the length of the rail. They are commonly used in manufacturing and warehouse environments.

- Gantry cranes: These cranes are similar to overhead cranes, but they have legs that support them instead of being mounted on rails or beams. They are often used in shipyards or to move containers.

Each type of crane has its own advantages and disadvantages, and the choice of crane will depend on the specific requirements of the construction site and the lifting task at hand.

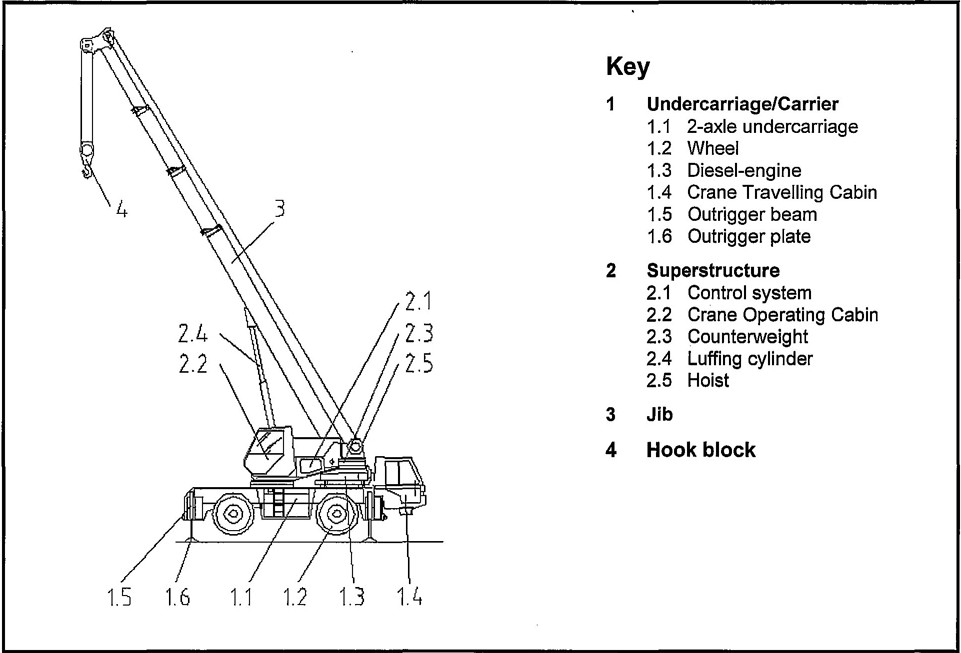

General parts of crane

Here are some of the general parts of a crane:

- Boom: This is the long, horizontal arm of the crane that is used to lift and move heavy loads. The boom can be fixed or telescopic, allowing it to extend or retract to different lengths.

- Hook: This is the device at the end of the boom that is used to attach and lift loads. The hook can be attached to different types of lifting equipment, such as chains or slings.A crane typically has two hooks: a main hook and an auxiliary hook. The main hook is the primary hook used for lifting heavy loads, while the auxiliary hook is a smaller hook used for lighter loads or for assisting with lifting tasks. The auxiliary hook is often used to attach rigging equipment, such as slings or chains, to the load being lifted. Having two hooks allows the crane operator to perform more efficient and versatile lifting tasks, using the appropriate hook for the specific load being lifted.

- Jib: Some cranes have a smaller, secondary arm called a jib that is attached to the end of the main boom. The jib can be used to extend the reach of the crane or to lift loads at an angle. To use Jib 3rd party inspection certificate is required

- Counterweight: A counterweight is often used to balance the weight of the load being lifted and to provide stability to the crane. It is typically a large weight that is attached to the opposite end of the crane from the load.

- Cab: The cab is the enclosed area where the crane operator sits and controls the crane’s movements. The cab is usually located near the top of the crane and provides a clear view of the construction site.

- Outriggers: Outriggers are extendable legs that provide additional support and stability to the crane. They are typically used when lifting heavy loads or when the crane is operating on uneven ground.nal support and stability to a crane when it is lifting heavy loads or operating on uneven ground. The outrigger is an extendable leg that is positioned perpendicular to the crane and is supported by a spreader plate, which is a large plate that spreads the weight of the outrigger over a larger surface area.

- Spreader mates (plates): The spreader plates prevent the outrigger from sinking into the ground and provide a stable foundation for the crane to operate on. When the crane is not in use, the outriggers can be retracted and stored on the crane itself. The use of outriggers with spreader plates is an important safety feature that helps prevent the crane from tipping over during lifting operations.

- Anti tube block/limit switch: An anti-two-block system is a safety feature on cranes that prevents the hook block and load block from colliding. It uses a limit switch that triggers when the hook block is raised too high, sending a signal to the crane’s control system to stop the hoist and prevent the collision. It is an essential safety feature required by law in many jurisdictions.

- Center Pin : A center pin is a part of a crane’s boom system that connects the different sections of the boom together. It is typically located at the base of the boom and allows the boom to be extended or retracted as needed. The center pin is designed to withstand heavy loads and is an essential component of the crane’s lifting system. It is important to ensure that the center pin is properly lubricated and maintained to prevent damage and ensure safe and efficient operation of the crane.

- Superstructure : The superstructure of a crane refers to the upper portion of the crane that houses the crane’s machinery and components. It includes the cab, engine, counterweights, and boom system and is designed to be strong and stable to support heavy loads and allow the crane to maneuver with precision. It is an essential part of the crane’s overall structure and must be properly maintained for safe and efficient operation.

These are some of the general parts of a crane, although the specific parts and features of a crane will vary depending on the type of crane and its intended use.

Lifting & Crane Hazards:

Shifting of materials from one place to another place using Crane and Boom truck (Lifting) is a critical work which has the following hazards:

- Load falling: When lifting a load, there is a risk of it falling, which can cause injuries to people and damage to property.

- Hitting and crushing: Loads can swing and collide with existing facilities, causing damage or injury.

- Crane toppling: If the crane is not properly set up or overloaded, it can topple over, potentially causing serious injury or death.

- Environmental factors: High wind speed, poor communication, and poor visibility can also contribute to crane accidents.

- Damage to underground utilities: When moving heavy loads, there is a risk of damaging underground utilities or other infrastructure, which can be costly and dangerous.

- Electrical hazards: When working near power lines or electrical equipment, there is a risk of electrocution, which can be fatal.

- Inadequate training: Operating a crane or boom truck without proper training and certification can result in accidents and injuries.

- Equipment failure: Equipment failure can occur due to a lack of maintenance or faulty parts, leading to accidents and injuries.

- Human error: Accidents can also occur due to human error, such as miscommunication or improper use of equipment.

It is important to take appropriate safety measures and precautions when using cranes and boom trucks to ensure the safety of personnel and property.

Lifting & Crane safety precautions

- Check and level ground conditions: Before operating a crane or boom truck, the soil or ground conditions should be checked and leveled to ensure stability and prevent accidents.

- Use appropriate spread mate size: A spread mate size of 1:3 should be used to ensure that the load is evenly distributed and the crane is stable.

- Fully extend outriggers: The outriggers should be fully extended and at least 1 meter away from manholes and trenches to provide maximum stability and avoid accidents.

- Do not overload: Always lift up to the safe working load (SWL) and avoid overloading the crane or boom truck, as this can result in equipment failure and accidents.

- Follow regulations: Crane and boom truck operations should be performed according to the regulations set by the relevant authorities, such as KNPC, and the crane should not be used beyond 75% of its capacity.

- Avoid adverse weather conditions: Crane and boom truck operations should not be performed in high winds or raining conditions, as this can increase the risk of accidents and injuries.

- Barricade the swinging radius: The swinging radius of the crane should be barricaded, and only trained and certified riggers should be allowed in the area.

- Wear appropriate personal protective equipment: Riggers should wear jackets or other appropriate personal protective equipment.

- Proper communication protocols: The only rigger should give signals to the crane operators, and a minimum of two tag lines should be used to control the swinging of the load. Miscommunication or misunderstanding of signals can result in accidents and injuries.

- Avoid man entry: Under no circumstances should anyone be allowed under the suspended load, even if they are a rigger.

- Use appropriate hitching methods: Straight, basket, and choker hitching methods should be used to secure the load properly and prevent accidents.

- Reverse beep horn: The crane should have a reverse beep horn to alert workers and prevent accidents while the crane is in motion.

- Regular inspections and maintenance: Regular inspections and maintenance of the crane and its components can help to identify any issues that may increase the risk of accidents and prevent equipment failure.

- If multiple cranes are being used, a risk assessment should be performed.

What are the things we have to check in cranes?

When inspecting a crane, the following items should be checked:

- The crane’s third-party certificate should be checked for validity, plate number, any remarks, and number of falls.

- The operator’s third-party license should be checked.

- The rigger’s third-party certificate and its validity should be checked (valid for one year as per KNPC).

- The crane’s safety certificate and fire extinguishers should be checked.

- The outriggers and mates of the crane should be inspected.

- The crane’s computer function should be tested.

- The anti-tube block/limit switch, which prevents the crane hook from touching the top boom pulley, should be checked.

- The lifting appliances (e.g. wire rope sling, webbing sling, D shackle, chain block) should have a third-party certificate with a validity of 6 months (as per KNPC) and should not be used beyond their safe working load (SWL).

- Any lifting tools or tackles that are damaged or expired should not be used.

- The safety latch of the main and auxiliary hooks should be checked.

- The crane should be inspected for hydraulic oil leaks.

- The crane’s cabin should be free of blind spots.

- Working crew members should wear appropriate personal protective equipment (PPE), including leather gloves for riggers and safety harnesses.

Credits: This article was originally posted at Safety Notes Website.